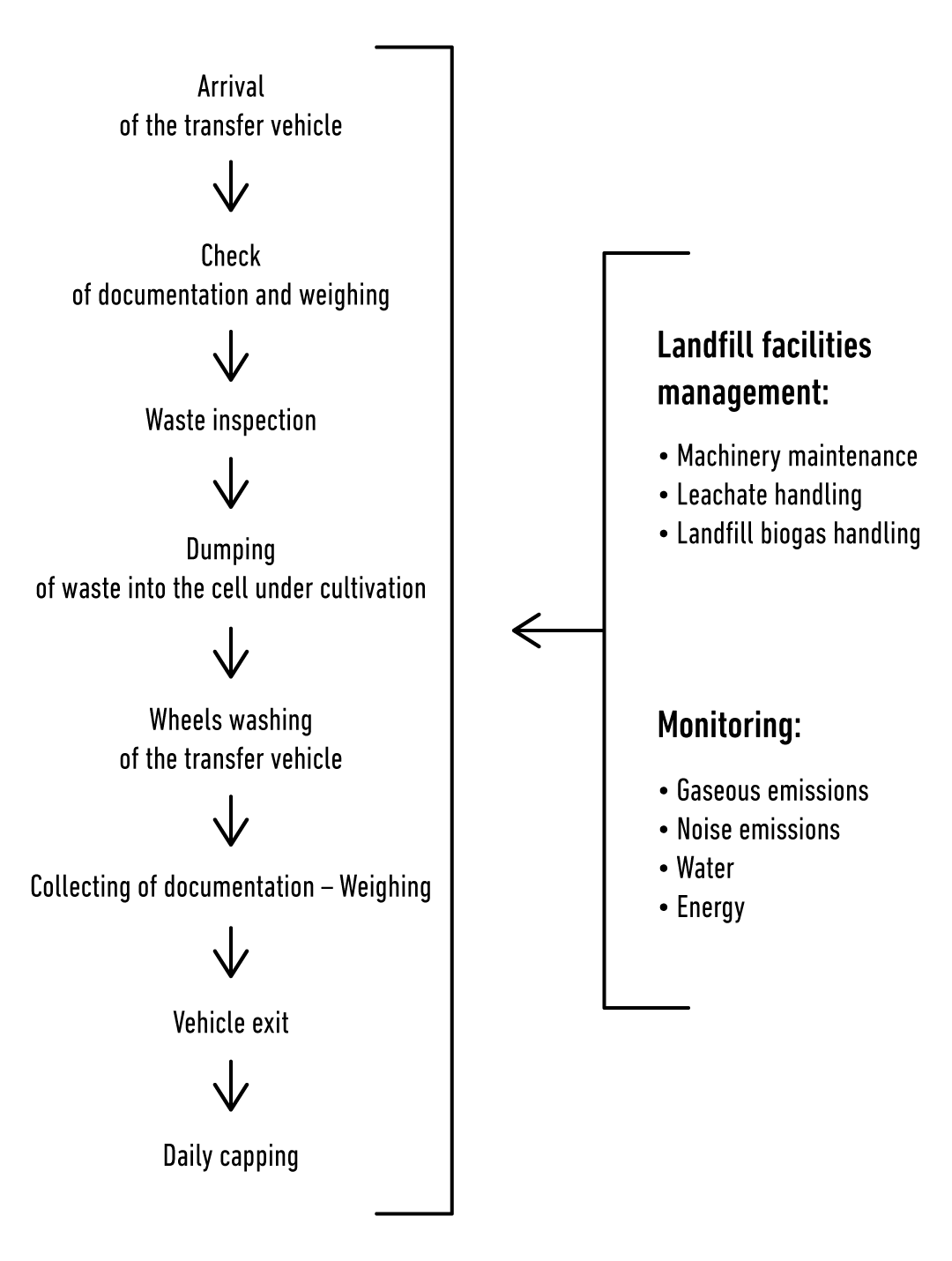

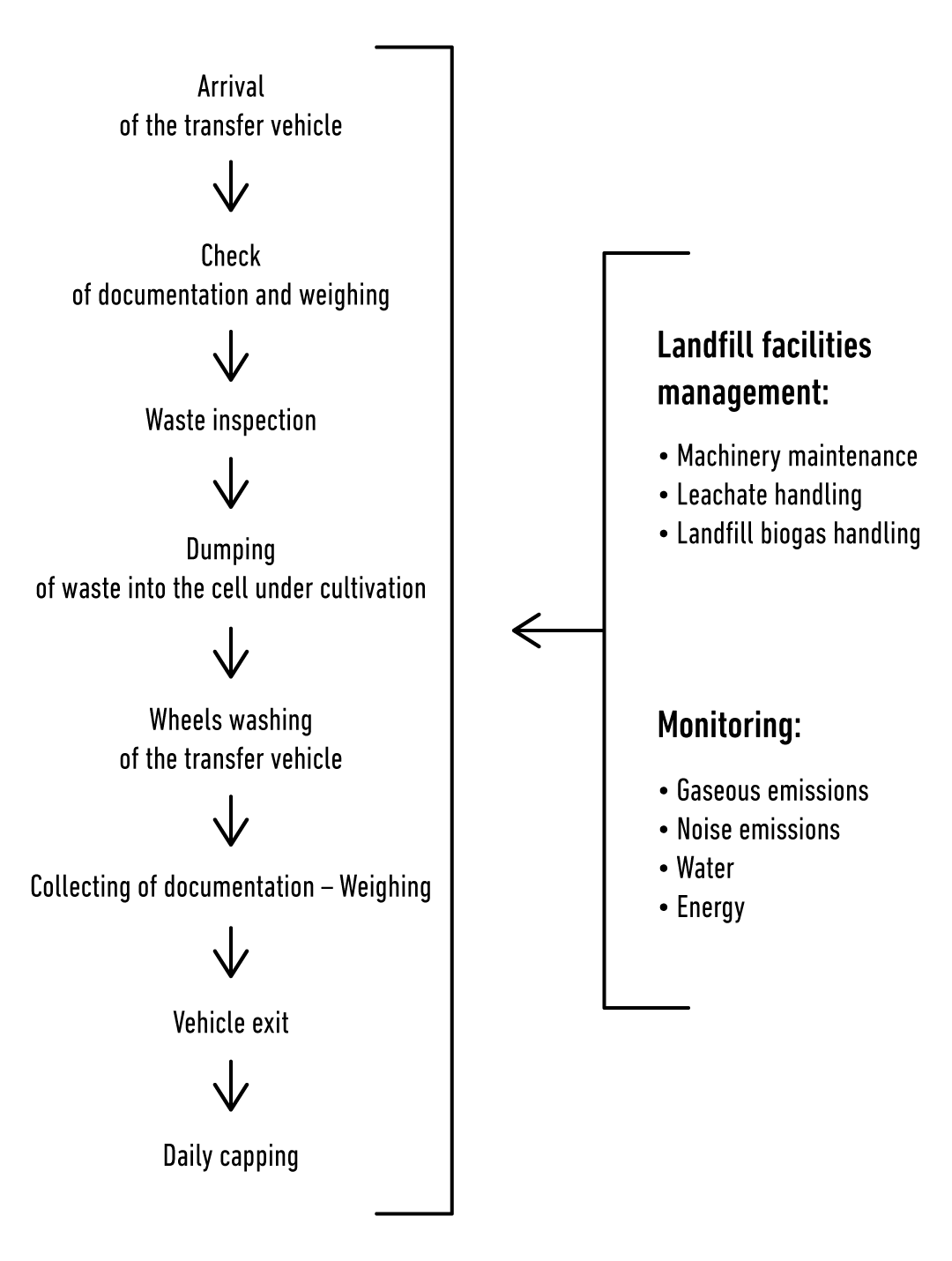

Following the transfer request, special non-hazardous waste is preliminarily subjected to an analytical verification of conformity and, for this purpose, placed in “pre-storage”. If the verification gives a positive result we proceed with the approval, after the waste can be accepted in the plant. However, in the case the analytical results show the non-conformity of the waste, the waste is rejected to the sender, with relative annotation on the form that accompanied the cargo at the plant. Downstream of the homologation procedure, the waste is managed as per the flow chart shown in the following figure.

Complete Process Management

Validation

Each refusal, included among those accepted for license and sent to landfill for the first time, must, before anything else, overcome the stage of validation, for which we require to our potential customers:

– demand for disposal

– basic characterization of the waste

– analysis of waste

– a sample of waste

– application form for validation

If the waste is compliant with the landfill acceptance criteria, established by the license and the relevant regulations, the waste is validated and approved.

Preliminary analytical verification

Last preliminary step before acceptance is the analytical verification about conformity of the waste. It is performed at first load each time and it is performed again, and periodically repeated (at a frequency not exceeding one year). This verification can be performed in any case where we deem doubts about the conformity of waste, or simply on random sampling. In the case of analytical verification, the cargo subject to control is placed in an area of the landfill, suitably marked, not affected at that time by the activity of cultivation, for the time strictly necessary for carrying out analytical investigations. After, we proceed to the taking of n. 2 representative samples of waste and the preparation of a synthetic sampling report, signed by both the responsible of the sampling and the conveyor. Immediately after sampling, the tested waste is marked with an identification plate of the cargo.

The two samples are distributed as follows:

- one is stored in the landfill for at least two months available for the regulatory Authorities

- one is delivered to a trusted laboratory for testing analytical compliance

Whenever a waste to be set aside for investigations aimed at analyzing the state of compliance, of whatever nature or duration, it will be marked in the appropriate “Control Register” that sets forth the details of the identification form, the description of the waste at issue, the investigations carried out and the outcomes of the investigations. If the analytical results prove the non-compliance of the waste, the waste is returned to the sender, with its record on the form that accompanied the cargo at the facility. By notice in writing, the customer is consistently called on to provide for the pick up of the cargo no later than 48 hours from receipt of the same.

If the analyses confirm that the waste complies with disposal requirements, we proceed as per standard operating procedures summarized in the flow chart, identical to those established for waste not checked.

Acceptance

The first step of the acceptance of waste, that is the delivery of the waste identification form, consists in checking the documentation and the weighing of the gross. In fact, if the documentation and waste comply, also in light of a visual inspection of the cargo, the second step involves entering the vehicle into landfill and weighing of gross (the vehicle loaded).

Dumping

Third step: the dumping (i.e. the final deposition of waste in landfill) during which there’s a second visual inspection; upon completion of this step we affix the stamp on the certificate of disposal on the waste identification form. Then a note is drawn on the Register of Material Loaded and Unloaded of the landfill, as established by art. 190 of Italian Legislative Decree no. 152/2006.

Scattering and compaction

Scattering and compaction phases represent the fourth step and are performed using mobile vehicles supplied to the landfill. Compaction is a very important step because it determines the degree of softness of the successive layers of waste; the greater the compactness conferred, the smaller will be the extent of the settling phenomena.

Cleaning wheels and weighing tare

After the dumping, and before the vehicles leave the plant, they are subject to washing of the wheels and the tare weighing (weighing of unladen vehicle).

At this point the vehicles may leave the plant. The water used for washing the wheels of vehicles does not cause water drains as conveyed in an Imhoff tank (authorized), periodically emptied.

The collected water then is treated as waste and directed to the disposal at authorized facilities.